- Home

- Fiber Drum Machine

Fiber Drum Machine

The fiber drum machine is capable of producing fiber drums of various sizes. These fiber drum machines can be helpful for packaging paper drums in food, chemical and chemical fields.

The fiber drum machine integrates several high-efficiency automation equipment. A fiber drum production line consists of five machines, automatic drum winder, automatic laser welding machine, automatic edge milling machine, automatic hydraulic bottom sealing machine and stacked edge punching and tying machine. Each piece of equipment plays an important role in the production process, enabling the plant to efficiently and consistently produce high quality fiber drums that meet a variety of specifications and requirements, thus achieving the goal of realizing different customers’ drum manufacturing and packaging needs.

Fiber Drum Making Machine’s fiber drum production lines offer significant production advantages by integrating advanced automation equipment and technology. We ensure an efficient, reliable and high quality process for the production of paper drums. We guarantee precision accuracy in every processing step, as each of our drum making machines is equipped with advanced control systems. At the same time, laser welding, precision lapping and hydraulic bottom sealing technologies ensure the strength and sealing of fiber drums, allowing the production of strong and durable paper drums.

Fiber Drum Production Line

A fiber drum production line has 5 making machinery: automatic drum rolling machine, automatic laser welding machine, automatic edge milling machine, automatic hydraulic bottom sealing machine and lock ring making machine.

Fiber Drum Making Machine provides the best iron hoop fiber barrel manufacturing machines. We provide unique and best solutions for the production of paper buckets with different needs of our customers. Fiber Drum Making Machine provides reliable, efficient and high-quality fiber paper barrel with iron hoop production solutions to help customers increase production capacity, reduce costs, and meet market demand.

Automatic Fiber Drum Rolling Machine: The barrel rolling machine is the primary and very important machine in the paper barrel production line. It includes steps such as slitting paper, automatic paper feeding, automatic gluing, automatic heating glue, automatic paper cutting, automatic reel, and automatic discharge barrel.

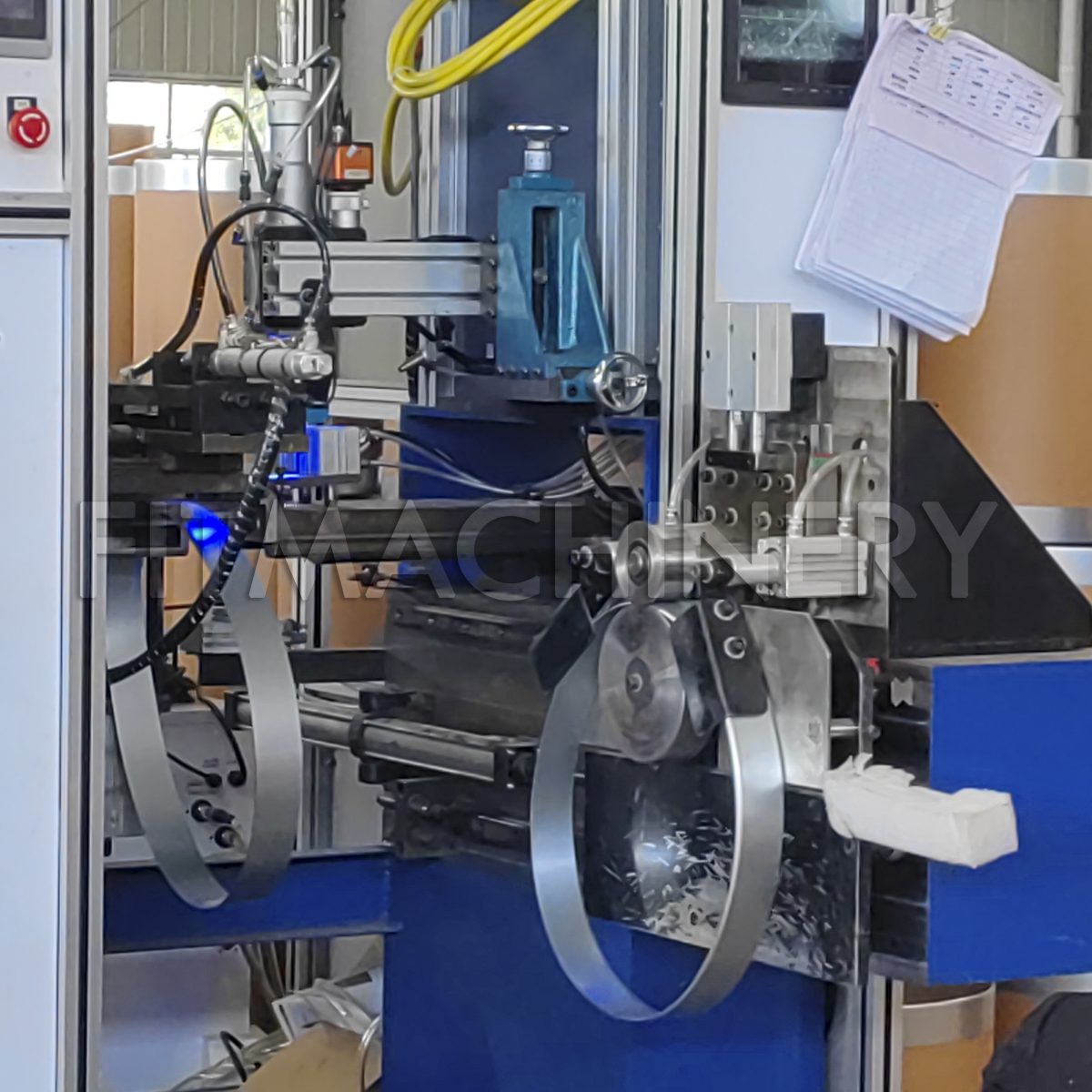

Automatic Laser Welding Machine: The automatic laser welding machine is mainly used for the steel strip discharging, welding and edging process of iron hoop pail and welding wire pail.

Automatic Edge Milling Machine: The automatic edge rolling machine features an attractive design and robust construction. It completes the edge rolling of both the barrel top and bottom in one operation, ensuring high edge rolling quality.

Automatic Hydraulic Bottom Sealing Machine: Automatic hydraulic back cover machine is widely used in the production of fiber barrels, metal barrels and other containers. The hydraulic system is used to apply uniform pressure to ensure that the sealing of the bottom of the barrel is firm and reliable.

Lock Ring Making Machine: The metal ring hoop making machine is used for rolling iron hoop and locking ring for fiber paper drum. The metal ring flanging machine is the last step of the iron hoop barrel making line.

FAQs about Fiber Drum Production Line

- What is the workflow of the iron hoop barrel production line?

Workflow of the iron hoop barrel production line:

Raw material preparation: load the sheet metal onto the automatic barrel rolling machine.

Barrel rolling forming: The automatic barrel rolling machine rolls the metal plate into a cylindrical shape.

Laser welding: The automatic laser welding machine welds the joints of the barrel body to form a complete cylinder body.

Edge treatment: The automatic edge milling machine performs piping treatment on the upper and lower edges of the barrel body.

Back cover: The automatic hydraulic back cover machine seals the bottom of the barrel with the barrel body.

Tie hoop treatment: The stacking punching tie hoop machine completes the folding, punching, and iron hoop installation of the barrel edge.

- What is the production capacity of the paper bucket production line?

The making production capacity of the fiber barrels depends on the specific equipment configuration and product specifications. Generally speaking, the standard iron hoop barrel production line can produce hundreds of iron hoop barrels per hour.

- Are all the equipment of paper drum production line easy to operate and maintain?

Yes, Fiber Drum Making Machine’s hoop drum production line is designed to be user-friendly, with simple and clear operation interface, which is easy for workers to operate. The equipment is easy to maintain, and the company provides comprehensive after-sales service and technical support to ensure the long-term stable operation of the equipment.

- Can all the equipment of paper barrel production line be customized according to the requirements?

Of course, Fiber Drum Making Machine provides customized service, we can adjust the parameters and configurations of the equipment according to the specific needs of customers, to meet different requirements of fiber paper drum production.

- How long does it take to install and commission a production line?

The installation and commissioning of a production line depends on the specific situation. In general, it takes a few days to a few weeks from the arrival of the equipment at the customer’s plant to the completion of the installation and commissioning. Fiber Drum Making Machine’s technical team will support you throughout the entire process, and our specialized technicians will be able to make the commissioning on-site to make sure that the plant can put the production line into operation without any problems.

- Does Fiber Drum Making Machine provide after-sales service for its paper drum production line?

Fiber Drum Making Machine provides comprehensive after-sales service, including equipment warranty, technical support, spare parts supply and regular maintenance. Customers can contact our after-sales service team at any time, we will give you timely feedback and help.